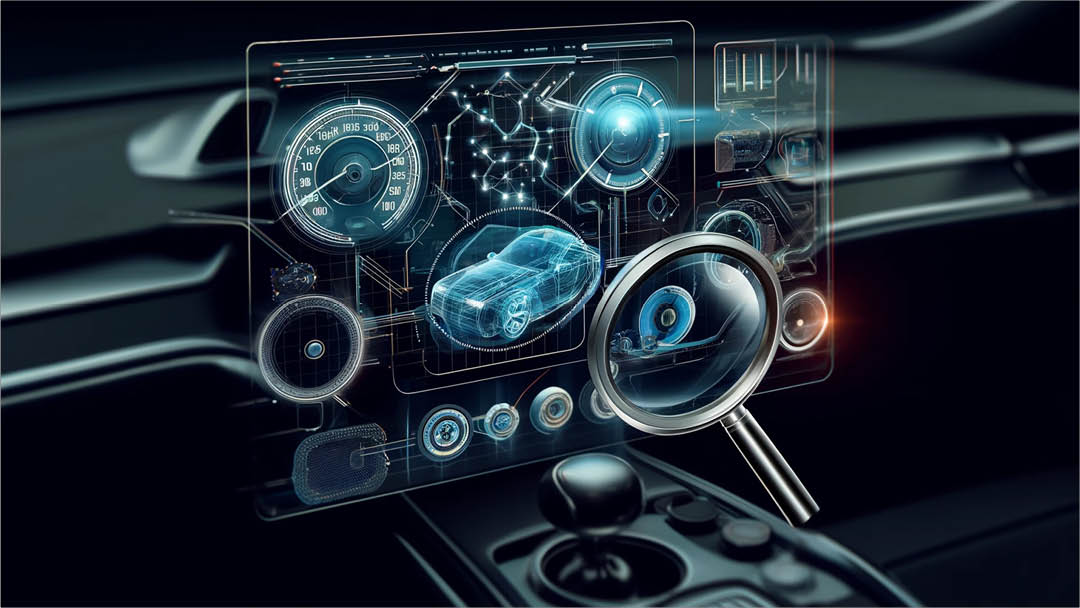

In Brief Modern digital cockpits are complex systems-of-systems (SoS), necessitating meticulous software integration and comprehensive validation to ensure reliable, safe, and user-friendly in-vehicle experiences. Integration goes beyond simply combining software...